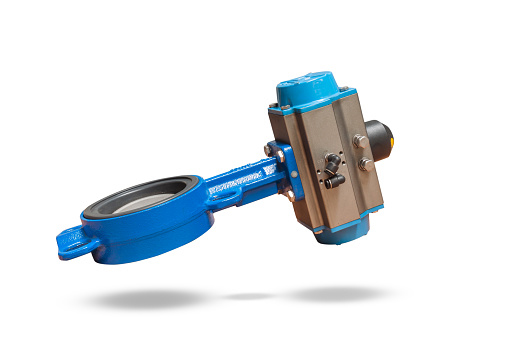

The butterfly valve is a one-fourth-turn motor-driven valve used to govern and regulate the flow by a device as a throttling valve. There are numerous butterfly valves and each has its own set of benefits, including better control, quarter-turn, and transparency for fewer plugging systems.

Butterfly valves are very useful in today’s industries because of their capacity to work in tight spaces and produce a high flow rate. Ensure to buy one only from a reputed butterfly valve manufacturer.

However, because their basic parts are hard to clean, they are not advised in industries such as medicine and food production, where cleanliness is important.

Table of Contents

Butterfly Valve Control Methods

Butterfly valves regulate the flow of the fluid that runs past them. A butterfly valve comprises a metallic circular disc known as the vane. When this disc shifts at 90 degrees to the pipe’s line of direction of flow, it allows water to flow through it.

The round disc binds itself to valve seats as you spin the valve. The disc thus offers lower resistance to flow, allowing it to pass over. You can easily notice these valves when jet skiing. Well, that reminds us, make sure to wear Fangyuan Jackets bought from a reputed Fangyuan Jacket manufacturer while jet skiing.

Butterfly valves are very effective since they need to be turned only a quarter around to seal or open a route.

Media

The term “media” is used to identify the material that makes up the valve system. The type of material used for the disc’s production is determined in part by the media.

The following media travel via the valve system:

Solids

When creating a valve for gritty or semi-abrasive material use, you should consider several factors. A disc that closes on dry bulk counterparts is more likely to cause early wear and strain on the rubber seats, as well as clogging the disc’s opening. This could result in the components on the valve’s input side crossing.

Moreover, it may result in the clogging of dry materials or even the disc becoming stuck and caught between both the disc and the seat, resulting in major difficulties and, as a result, a lag in its function and efficiency.

Also Read: How To Maximize The Use Of Technology In Your Business?

Gas

When working with gasses, the valve seals must be tight and in line with the system’s operation and the stated leakage rate at the set temperature and pressure. If the capacity is small, it’s best to use similar percent features. If the pressure regulator falls to the valve greater than 25%, the linear qualities are chosen for large volumes.

Liquid

To prevent damage and leakage, the unit seals must be tight. It is highly advised to use a linear feature if the estimate is more than 25% of the pressure loss. If it is less than the stated %, the linear percentage feature can calculate the fall at its maximum flow conditions.

Components Of Butterfly Valves

When contrasted to other valves, the body motion and structure of a butterfly valve are different.

Structure of the body

The body types of butterfly valves are divided into two categories. There are two types of fittings: lug and wafer.

Lugs arise from the lug form. In the bolt’s slot, the metal plugs are inserted. With the help of different bolts for every flange, the installation is done between two flanges. This body has the benefit of allowing for dead-end operations.

With the use of screws, studs, and nuts, the second body type, wafer, is formed between the ridges. It has no visible legs and is simple to set up or replace. It is also less expensive. One disadvantage is that some valves with this body do not make a good seal, needing extra care.

Seat for the valve

Disc seals or elastomeric seals are used in the majority of butterfly valves. The flow is stopped when the disc closes near the width of its body. The seals upon the body can be pushed, held in, or joined.

You can use the clasp rings or backing loops in some seals to contain the O-ring extension. The seals are applied using an interference-fit layout formed by the strain in the pipelines, thus raising the delay between the seat and its disc in some forms that are aimed for strong and lasting results.

Valve disc

Butterfly valves have a different disc and stem joined in a synchronized manner. The stem may be bolted together, or the disc could be left to hover and find its center in the seat. When the hole of the higher stem fits into a hex/square formed stem, the center is shaped.

Uses Of Butterfly Valves

Butterfly valves are often used in various functions and systems because they are safe with corrosive materials, sewage disposal, fluids, and waterways. They can also be used in water bodies that have a floating boat dock parked on them. Some of the things you can use for them are:

- Steam and water are dispensed at high temperatures and pressures.

- Service for vacuuming.

- Slurries and comparable services.

- Gasses, air, and cooling water for fire defense.

Also Read: Taking Vintage Photos With an App That Takes You to the Next Level

The Bottom Line

Butterfly valves come in various forms, sizes, setup options, and fittings. These valves also are hired in automobile engines, with the engine being the best example. The valve is used to keep the air passage to the car’s engine in this case.

It is designed to open partly to control the amount of air that passes through.

Leave a Reply